Are you new to using a micrometer and not sure where to start?

Don’t worry, you’re in the right place! This article will give you a step-by-step guide on how to use a micrometer correctly and with confidence.

You’ll learn about the different parts of the micrometer, how to read the measurements, and even some tips and tricks to help you out.

Check out the secrets to mastering micrometer measurement.

Table of Contents

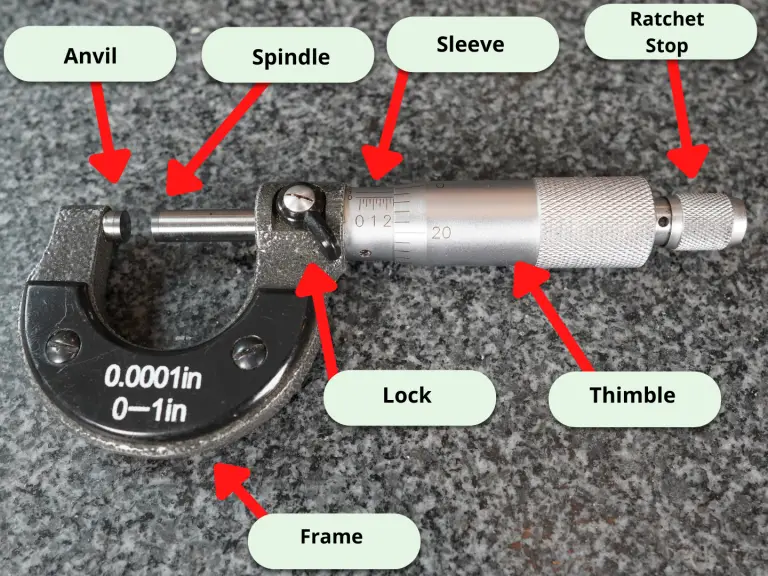

Before we talk about taking measurements with our micrometer, let’s have a quick refresher on the various parts of the micrometer.

Alright, let’s get down to business.

I’m assuming you’re ready to take your measurement now.

If you need tips for getting ready to take your measurement then skip to the bottom where we have some advice laid out.

For everyone else, grab your micrometer and your part to measure.

To take the measurement we are going to take four separate readings from the micrometer and add them up for our final reading.

Put the part in between the anvil and spindle of the micrometer.

This might require you to spin the thimble to open the micrometer enough to get the part in there.

Now spin the thimble until it closes on the part.

Remember you aren’t trying to clamp down on the part.

Use a gentle, consistent amount of force when spinning the thimble. Using the ratchet on your micrometer can make this easier. Try spinning the thimble until you get three clicks on your ratchet.

We’ve done that now and we have the reading below on our micrometer.

So let’s break down the four parts of this reading.

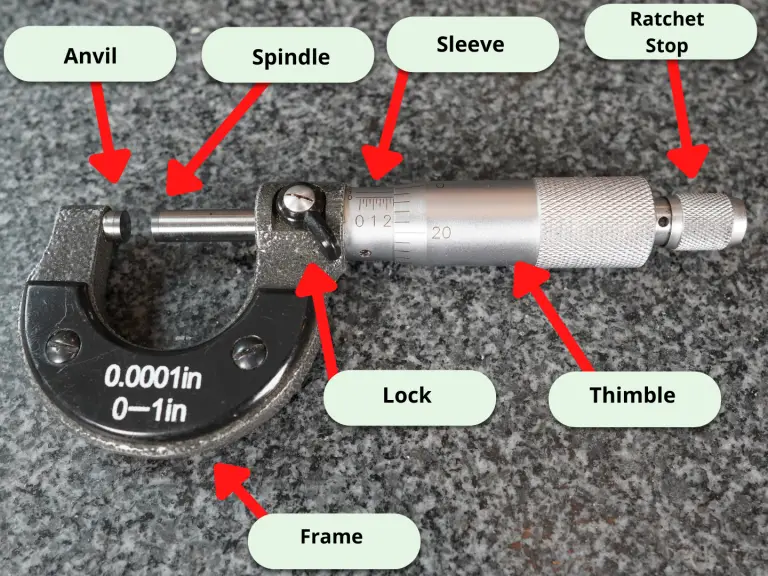

The first part of the reading is the 0.1000″ reading. This is our hundred thousandths or “hundred thou” reading.

In the example above we can see that the larger lines on the sleeve of the micrometer are numbered.

Each of these larger lines equals another 0.1000″.

We are taking our readings at the intersection of the lines on the thimble and the sleeve. Because the 3 is the last hundred thousandths graduation shown, the first part of our reading is 0.3000″.

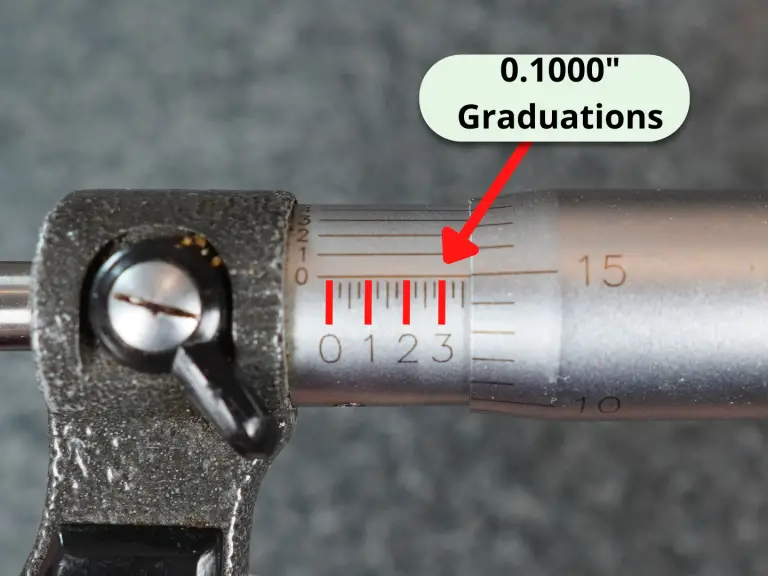

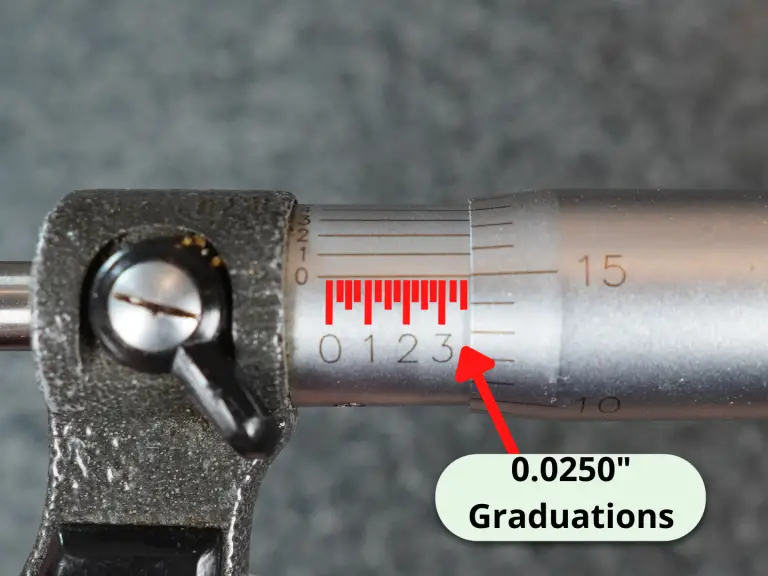

Next is the 0.0250″ or 25 thousandths reading.

This reading is also taken from the sleeve of the micrometer.

Each of the lines on the sleeve equals another 0.0250″. In our example, we can see two lines after the 3 which equals 2x 0.0250″ = 0.0500″.

This means so far our reading is 0.3000″ + 0.0500″ = 0.3500″.

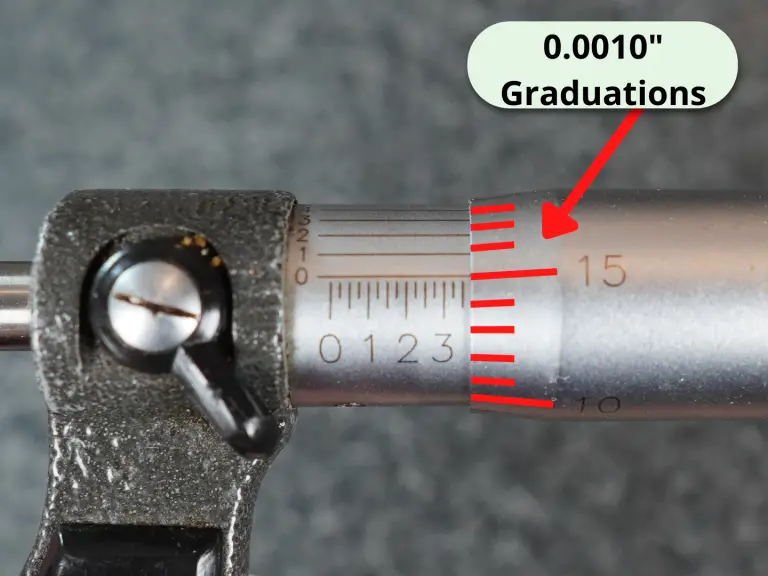

There are 25 lines around the thimble of an inch micrometer.

Each of these lines equals 0.0010″ or 1 thousandth.

In our example we can see that we are on the 15 so our reading is 0.0150″.

Let’s check in on our measurement so far.

We have 0.3000″ + 0.0500″ + 0.0150″ = 0.3650″.

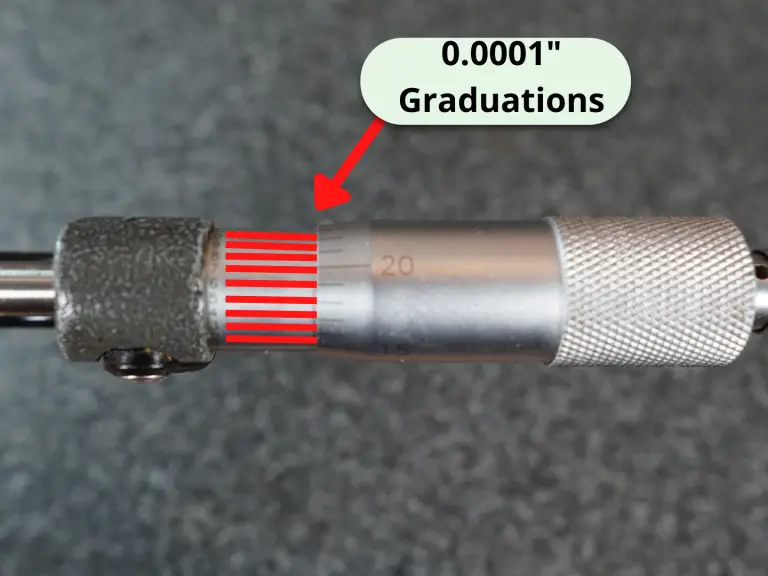

The last part of our reading is the tenths (0.0001″) reading.

Note: some micrometer don’t have a 0.0001″ reading. This is more common on older or very cheap micrometers.

To take the tenths measurement we look at the numbers that go around the sleeve of the micrometer.

We take the reading where the number on the sleeve lines up best with a line on the thimble.

In the pic above you can see that it looks like the 6 on the sleeve lines up best with a number on the thimble. This would make the final part of our reading 0.0006″.

We now have all four parts of our reading. The 1, 25 and 100 thousandths readings as well as the tenths reading.

If we add them all up we get 0.3000″ + 0.0500″ + 0.0150″ + 0.0006″ = 0.3656″

Note: our measurement was taken using a 0-1″ micrometer. If we used a 1-2″ micrometer then we would add 1″ to our measurement. If we used a 4-5″ micrometer then we would add 4″ and so on.

One last thing to keep in mind when taking micrometer measurements is that you should take multiple readings.

These are very accurate measurements and it is easy for something to go wrong.

Clamping too hard, being a little off angle or a piece of dust or lint can really throw off your measurement.

Taking multiple measurements helps build confidence that your measurements are correct.

To give you a little more practice let’s look at a few more readings.

All of these examples assume you are using a 0-1″ micrometer.

Here we have 0.1000″ + 0.0250″ + 0.0120″ = 0.1370″.

The tenths reading lines up with the zero so we don’t add any tenths.

Here we have 0.5000″ + 0.0500″ = 0.5500″.

The 1 thousandths (0.0010″) and tenths (0.0001″) readings lines up with the zeroes so we don’t add them to our measurement.

Here we have 0.7000″ + 0.0140″ + 0.0001″ = 0.7141″.

The 25 thousandths (0.0250″) reading doesn’t have any lines shown beyond the 0.1000″ reading so we don’t add anything to our measurement for the .

If our tenths reading lined up at the 9 as shown below. Our reading would instead be 0.7000″ + 0.0140″ + 0.0009″ = 0.7149″.

Reading your measurement correctly is important but so isn’t preparing to take your reading.

Pay attention to these factors before taking your measurement to help make sure your readings are accurate.

Dust and lint might seem small but they can make a huge difference in your measurement.

A human hair measures about 0.003″. Micrometers take measurements to an accuracy of 0.0001″ which is 30 times smaller. This is why everything has to be extremely clean.

You want to make sure your micrometer is in good working order.

Get a feel for it, literally!

If it feels like your micrometer is dragging or rubbing at any point when spinning the thimble, there is a good chance it could affect your measurement.

You want to take your measurements perpendicular (90 degrees) to the surface you are measuring.

Measuring at an off angle will skew your measurements and tend to give you a larger reading than the actual size.

Your micrometer should be calibrated but it also a good idea to check it right before using it.

The simplest way is to check the zero. Close the micrometer and check the reading to make sure it isn’t a tenth or two off.

If you have a larger micrometer then use a gauge block to check your zero.

Our examples are shown using a typical outside micrometer. However, there are many different types of micrometers available.

They all get read the same way.

Depth micrometers are probably the second most common type of micrometer. For most depth micrometer you will find that they don’t have a tenths (0.0001″) reading. Follow all of the same steps to read them but skip adding any tenths to your measurement.

Generally, calipers are less accurate and more versatile. Check out the comparison below to see how they match up.

Types of Measurements

Inside, Outside & Depth Measurements

Categories Measuring ToolsMachinist Guides is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com.

PH +1 603 287 8259

21 durham ave

claremont, Nh 03743

© 2024 Machinist Guides

Manage ConsentTo provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Functional Functional Always activeThe technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.

Preferences PreferencesThe technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.

Statistics StatisticsThe technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.

Marketing MarketingThe technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.